Service Hotline:

FAQ

When a thin-walled round pipe or rectangular thin-walled pipe fittings are welded to a thick plate, the welding rod is easy to burn through the thin-walled pipe part, in addition to the above two solutions, are there other solutions?

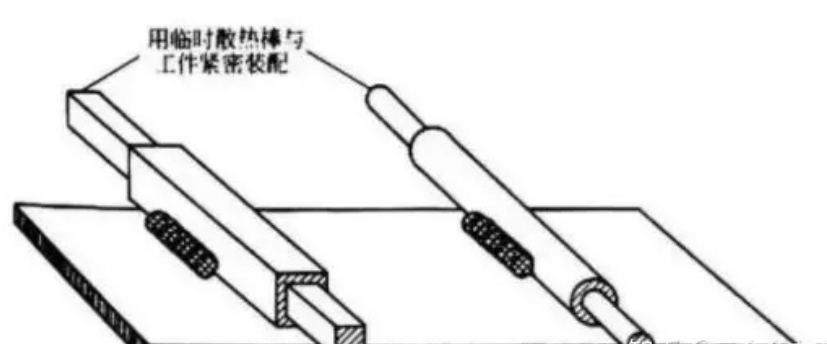

Yes, mainly in the welding process using a heat dissipation rod. If a solid round rod is inserted into a thin-walled round tube, or a solid rectangular rod is inserted into a rectangular tube, the solid rod will take away the heat of the thin-walled workpiece and prevent burnout. In general, solid round or rectangular rods are tightly fitted in most hollow or rectangular tube materials supplied. When welding, care should be taken to keep the weld away from the end of the tube, the end of the tube is the weakest area that is most prone to burnout. A schematic of using the built-in heat sink to avoid burn-through is shown in Figure 1.

Immediate consultation

Follow us

Contact us

Add: jinsuoyuan, wuliyao, Yanshan County, Cangzhou City, Hebei Province

Mobile phone:+86-13731702211 / +86-18630702211

Tel:+86-317-6393118

Email:a17778873989@163.com

Follow website

HeBei Cangrui Pipe Manufacturing Co., Ltd Powered by www.300.cn | SEO | Business license